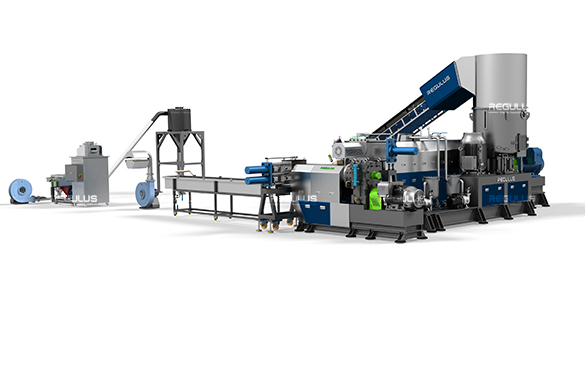

Mpempe akwụkwọ okpukpu abụọ nke compacking na-emegharị ahịrị pelletizing

Nkowa

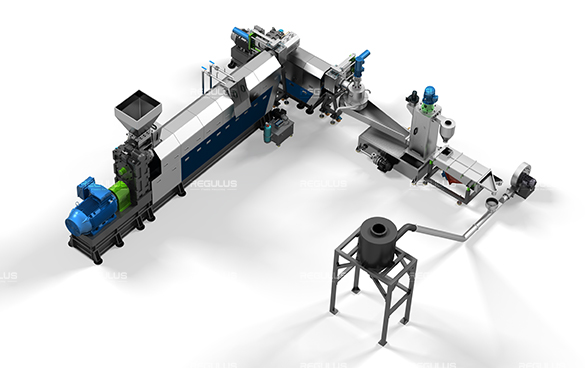

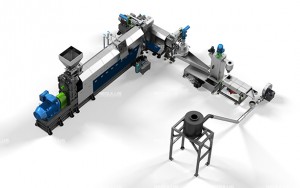

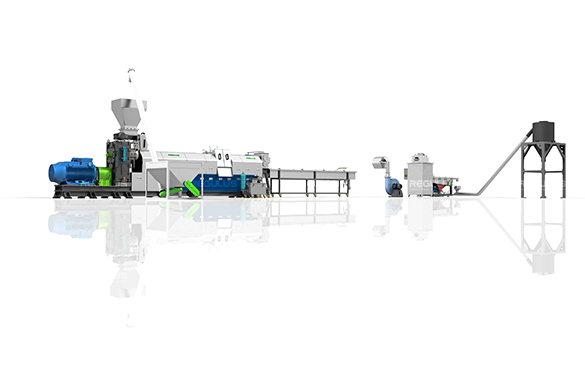

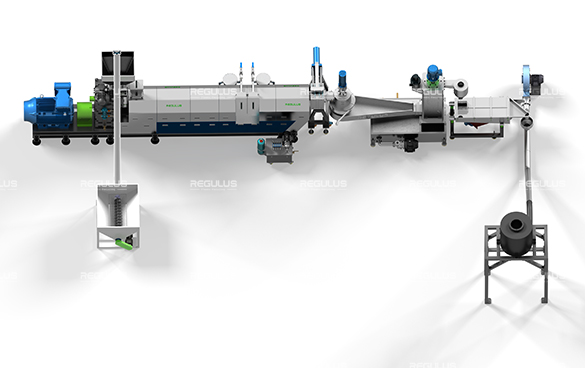

| Ichegharị ihe eji eme ihe | HDPe, LDPE, PP, BPP, CPP, OPP, PA, PA, PS, PS, PS, PS, PSP | |||||

| Ihe mejupụtara usoro | Ibu Ibu Ibu Ibu, Ntinye Aka, Mgbanwe, Ntinye Mmebe, Pleletizer, Ngwa ngwa Ngwa, Ngalaba Doneyor, Prove | |||||

| Akụ nke ịghasa | 38crmoala (sacm-645), bimetal (nhọrọ) | |||||

| L / d nke ịghasa | 28/1, 30/3, 3/1/1/1, (dị ka njirimara nke recyling) | |||||

| Kpo oku nke gbọmgbọm | Seramic kpo oku ma ọ bụ igwe na-efe efe | |||||

| Jụrụ gbọmgbọm | Airgbọ mmiri na-agba ọkụ | |||||

| Peeltizingdị ụdị | Mmiri na-adọta mmiri | |||||

| Ọrụ teknuzu | Nhazi oru ngo, Ewu ulo oru, ntinye na aro, Commilinsing | |||||

| Ihe nlereanya igwe | L / d | Otu ndọpụ uche | ||||

| Sụchaa dayameta | Ewepu moto | Ike mmepụta | ||||

| (mm) | (kw) | (kg / h) | ||||

| Xy100 / 100 | 100 | 28 | 75-90 | 200-300 | ||

| 10 | 22-30 | |||||

| Xy120 / 120 | 120 | 28 | 90-110 | 250-400 | ||

| 10 | 30-37 | |||||

| Xy130/10 | 130 | 28 | 132 | 450-550 | ||

| 10 | 45 | |||||

| Xy160 / 180 | 160 | 28 | 160-200 | 550-850 | ||

| 10 | 55 | |||||

| Xy180 / 200 | 180 | 28 | 220-250 | 800-1000 | ||

| 10 | 75 | |||||

Mpempe akwụkwọ okpukpu abụọ nke compacking na-emegharị ahịrị pelletizing

Usoro a na-agbasa na usoro nhicha ahụ bụ usoro a pụrụ iche ma nwee ntụkwasị obi, dabara adaba na recletizizizi ọrụ nke philap plastik ike. Ọ na-agwakọta ọrụ nke rọbalization na palletizing ruo otu ụzọ ma dị mma maka nkụda mmụọ ma ọ bụ floaks nke pe ps / ps / hips / úkwù / PC wdg.

Mkpokọta ikpeazụ na-emepụta site na ụdị a na-eme nke ọma na ụdị pellets / granules, nwere ike itinye ya na ihe nkiri maka ihe nkiri

Igwe nri na-enye nri

Ọkpụkpụ ma ọ bụ nnukwu frish mgbe a gwepịara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara awara, kewaa ya site na oghere nzacha. Dabere na dayameta sọọsọ nke otu ịghasa, ihe a na-ahụkarị nwere ike ikpuchi site na 100kg / h ruo 1000KG / H, na-ebute motor moto: 2.2 kW. Na-akpọpụta paịlị nke nwere ihe eji arụ ọrụ, ọkpọkọ n'ime ọkpụrụkpụ bụ 2mm, dayameta ọkpọ bụ 102mm.

Isi nri (Volumetric)

Ọ ga-eri nri ihe ndị ahụ n'ime ndị na-eweta ya. Enwere ihe na-akpali agụụ iji zere mgbochi ihe na ala nke ndị na-eri nri. Nri Holper na ọkwa ọkwa.

Ọ bụrụ na ịchọrọ ijikọ ihe ndị ahụ, ndị na-enye nri ya bụ nhọrọ.

Otu ndọpụ uche

Ibelata anyị pụrụ iche na-eme ka ịmịnye ndọtị na-acha uhie uhie na-acha plastizes na homognizes ihe. Extrand Edider Bar bi-met nwere nnukwu mgbochi mgbochi corrisonion na-eguzogide, na-eyi eguzogide na oge ndụ.

Ugboro abụọ degassing zones

Site na mpaghara oghere abụọ, na-agbanwe agbanwe dị ka ụmụ irighiri mmiri na mmiri mmiri ga-arụ ọrụ arụmọrụ iji meziwanye ogo nke granules, karịchaa adabara maka nnukwu ihe ndị e biri ebi.

Planetdị ihuenyo na-agbanwe agbanwe

A na-eme ụdị efere a na efere nzacha abụọ. Enwere ọ dịkarịa ala otu nzacha na-arụ ọrụ mgbe ihuenyo ahụ na-agbanwe, na-agbaji na-ekpo ọkụ maka kpo oku na-agbanwe agbanwe

Ntụgharị Piston na-enweghị nzacha

1. A na-etinyekarị efere / Piston okpukpu abụọ nke na-agbanwe agbanwe ma ọ bụ nkwụsị okpukpu abụọ, piston anọ-ọdụ anọ nwere ike itinye isi nke Exuder iji gosipụta arụmọrụ operation.

2.Lonng ihuenyo ihuenyo, ihuenyo mgbanwe dị ala: ogologo oge na-agagharị na mpaghara ngwọta dị ukwuu.

3. Ọ dị mfe iji na ụdị na-enweghị nkwụsị: mgbanwe ihuenyo dị mfe ma ọ dịghị mkpa ịkwụsị igwe na-agba ọsọ.

4.Very na-akwụ ụgwọ ọnụ ahịa.

Usoro vertical mmiri

1. Ntinye aka na-edozi nke ọma maka mmachi kachasị mma na ogologo oge oge ekele ekele na-agbanwe agbanwe.

2. RPM nke agba ndị na-ebugharị na-akpaka dabere na nrụgide agbaze agbaze.

Telletizer Felletizer ngwa ngwa gbanwere, na-enweghị ọrụ ndozi na-azọpụtakwa oge.

Usoro mgbaaka na-asọ oyi

1. Ntinye aka na-edozi nke ọma maka mmachi kachasị mma na ogologo oge oge ekele ekele na-agbanwe agbanwe.

2. RPM nke agba ndị na-ebugharị na-akpaka dabere na nrụgide agbaze agbaze.

Telletizer Felletizer ngwa ngwa gbanwere, na-enweghị ọrụ ndozi na-azọpụtakwa oge.

Nkwuputa akọrọ

1.Made na-eme mkpọtụ na-eme ka ọ na-agbakọta na eriri afọ dị elu na-eme ka arụmọrụ dị elu na oke ike.

2. Achịkọtara ndị na-eme ihe nkiri: A na-etinye ndị na-efe efe ma dozie ya site na kposara ya kama ịgbado mmiri, yabụ ị nwere ike ịgbanwe ihe ndị na-esi na-aga n'ihu n'ọdịnihu.

Ihe eji eme ihe

A na-eji ihe pụrụ iche mee ihe na-egbu egbu nke mmiri mgbaaka na mmiri n'okpuru mmiri,

Ihuenyo na-emegharị

Na-ekewapụ nke na-amịpụta plastik